Table of Content

Lean Project Management has become a key strategy for teams striving to deliver maximum value. It streamlines work, eliminates unnecessary activities that do not bring value, and aligns every task based on customer needs. This encourages teams to work smarter, improve continuously, and ensure project outcomes align with stakeholder expectations and customer requirements.

It is both a mindset and a disciplined way of working that reshapes how projects are planned, executed, and reviewed. So, if you are ready to reduce delays, eliminate bottlenecks, and empower people to solve problems, keep reading this blog. Here, you will learn about Lean Project Management, its core principles, benefits, tools, and more.

What is Lean Project Management?

Lean Project Management is an approach that focuses on delivering maximum value to the customer while minimising waste in every form. Instead of just checking off tasks, it aims to deliver real value by reducing waste, saving time, and using resources wisely. It encourages agility, flow, and constant improvement rather than following a rigid structure.

It aims for fewer delays, fewer unnecessary steps, and better use of your team’s time and energy. Therefore, it streamlines workflows, reduces inefficiencies, and responds swiftly to change without compromising the project’s quality.

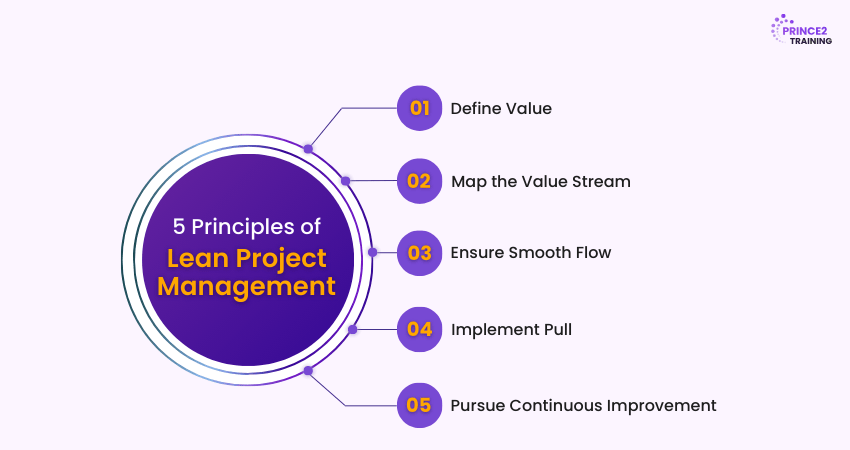

Principles of Lean Project Management

Lean Project Management is built on five principles that help to maximise value, reduce waste, and improve customer satisfaction. Here are those five core principles:

1) First Principle: Define Value

Begin by identifying what your customers and stakeholders truly value. This could be a product feature, a speedy delivery, or a cost-effective solution. Everything else that doesn't contribute to this value is considered a waste.

To Identify Value:

1) Talk to your stakeholders

2) Know their needs and expectations

3) Understand what success looks like from their point of view

2) Second Principle: Map the Value Stream

The next step is to map out every step required to deliver that value. For that, you can use Value Stream Mapping (VSM) to visualise your current project workflow from start to finish. Then, compare it to the older version that focuses only on tasks that directly contribute to value.

This Step Uncovers:

1) Redundant steps and project bottlenecks

2) Unnecessary approvals

3) Wasted resources

3) Third Principle: Ensure Smooth Flow

After removing waste, your goal is to create a smooth, continuous flow of work across your team. In Lean, delays, interruptions, or waiting times are the enemy of productivity. So, it will help tasks move from one stage to the next without delays, confusion, or clutter.

Techniques to Ensure Flow:

1) Use visual task boards like Kanban

2) Limiting Work in Progress (WIP)

3) Build cross-functional teams

4) Fourth Principle: Implement Pull

Traditional Project Management often “pushes” tasks onto teams whether they’re ready or not. Lean rejects that by creating a “pull” system where each stage should start only when the previous one is completed.

This Avoids:

1) Overloading team members

2) Piling up of unfinished tasks

3) Wasting time on work no one’s waiting for

5) Fifth Principle: Pursue Continuous Improvement

The final principle of continuous improvement, also known as Kaizen, is what turns Lean into a lasting habit rather than a one-time fix. Here, even if your workflow is running smoothly, your customers’ needs, tools, and team structure will always evolve. That’s why you need to keep improving how you work.

Tips for Continuous Improvement:

1) Hold regular meetings or check-ins

2) Collect team and customer feedback

3) Revisit your value stream and look for new inefficiencies

Plan, lead, and deliver successful projects with our Introduction to Project Management Course – Register today!

When to Implement Lean Project Management?

Lean Project Management is versatile and can be applied across various sectors. It is ideal for businesses that want to improve efficiency, reduce waste, and deliver better value to their customers, without adding extra resources. Here are a few common applications:

1) Manufacturing

Lean Project Management was born in manufacturing, making it a perfect match for factories and production-based industries. It streamlines production by cutting waste like excess inventory, idle time, and overproduction. It helps manufacturers lower costs, improve workflow, and deliver higher quality with fewer defects.

Ideal When:

1) Excess inventory or raw material costs are rising

2) Production bottlenecks are slowing down output

3) Quality issues or defects are becoming frequent

4) Delivery timelines are inconsistent

5) Equipment and labour aren't being optimally utilised

2) Construction

Construction projects often face unpredictable challenges like delays, resource shortages, and a lack of communication between teams. Lean Project Management introduces consistency through standardised processes and encourages frequent check-ins to identify issues early. It improves just-in-time delivery and reduces material waste.

Ideal When:

1) Delays are caused by scheduling or supply chain issues

2) Material costs are high due to waste or reordering

3) Project phases lack clear communication and coordination

4) On-site teams face overlapping responsibilities

5) Predictability and standardisation are lacking across projects

3) Product and Software Development

In the fast-moving world of software and product development, speed and adaptability are essential. Implementing Lean will help developers prioritise high-impact features, reduce unnecessary work, and minimise technical debt. This will help your teams deliver smaller, value-driven releases more frequently.

Ideal When:

1) Feature releases are slow or inconsistent

2) Developers are overwhelmed with large backlogs

3) Customer feedback is not integrated efficiently

4) Technical debt is growing rapidly

5) Priorities change often due to evolving market needs

What are Lean Project Management Tools?

Lean Project Management tools are practical methods that help teams improve processes, reduce waste, and deliver great value. Let’s look at the most used tools:

1) Deming Cycle (PDCA)

The Deming Cycle, commonly known as the PDCA (Plan–Do–Check–Act) Cycle, is a widely used framework for continuous process improvement. It helps teams test changes in a controlled manner and learn from results before making them permanent solutions. This ensures projects are aligned with business needs.

Key Stages of PDCA Cycle:

1) Plan improvements using clear objectives and data analysis

2) Implement changes on a small scale

3) Check results against expected outcomes

4) Standardising successful and refining unsuccessful changes

2) Kanban Methodology

Kanban helps teams by visualising workflow and improving work efficiency. It provides real-time visibility into task progression and highlights bottlenecks. This makes it easier for teams to balance workload and maintain seamless workflow.

Core Elements of Kanban:

1) Visualise work using boards with defined stages

2) Limit work in progress to reduce overload

3) Identify bottlenecks and improve workflow

4) Use a pull-based system to align with customer demands

3) Lean Six Sigma Techniques

Lean Six Sigma Techniques combine Lean’s focus on reducing waste with Sigma’s emphasis on quality and consistency. This is valuable for teams in analysing processes, reducing variation, and improving performance using data-driven methods.

Lean Six Sigma Focus Areas:

1) Analyse processes to identify waste and variation

2) Use data to find root causes of problems

3) Apply systematic improvement techniques

4) Measure results to ensure sustained improvements

4) DMEDI Framework

The Define, Measure, Explore, Develop, and Implement (DMEDI) Framework is used mainly for new process or product development. It provides a structured approach from defining requirements to implementing solutions, helping teams deliver improvements to meet business goals and customer needs.

DMEDI Framework Stages:

1) Define project goals and customer needs

2) Measure relevant data to assess current processes

3) Explore potential solutions

4) Develop refined solutions

5) Execute changes while monitoring outcomes

Learn the essentials of project delivery and advance your Project Management skills with the PRINCE2 Foundation Course - Join today!

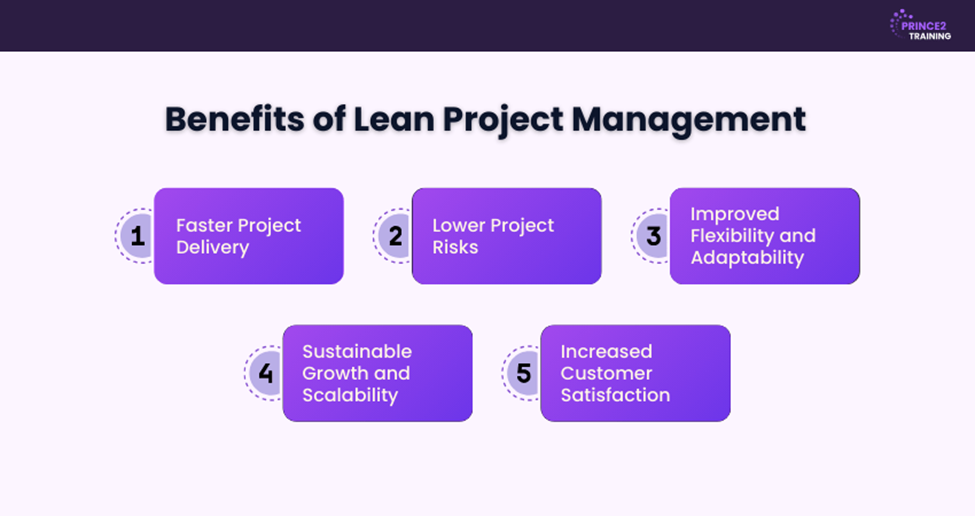

Benefits of Lean Project Management

Lean Project Management brings a wide range of benefits that help teams work smarter, move faster, and deliver better results. Here are its key benefits:

1) Faster Project Delivery

Lean Project Management focuses only on activities that add value to the project. Removing unnecessary steps and delays helps teams move faster. It eliminates bottlenecks and reduces rework for smoother execution and predictable timelines

2) Lower Project Risks

It helps to identify issues early through reviews and check-ins. This reduces the chances of major work disruptions. Maintaining focused planning, limits scope creep, and keeps projects manageable. This leads to transparent workflows and better decision-making.

3) Improved Flexibility and Adaptability

It breaks work into smaller, manageable tasks. This makes it easier to plan and collaborate for encouraging faster problem solving. With iterative planning and execution, Lean Project Management reduces reliance on rigid timelines and balances workload while increasing agility.

4) Sustainable Growth and Scalability

It supports sustainable growth by building a culture of continuous improvement. Teams are encouraged to review processes regularly and make meaningful improvements. This reduces waste and promotes innovation and process ownership, ensuring growth is steady and value focused.

5) Increased Customer Satisfaction

It places customer needs at the centre of planning and execution. This ensures projects solve real problems, leading to better quality outcomes. Consistent value delivers, builds trust, and strengthens customer relationships, leading to higher satisfaction and loyalty.

Lead projects with precision and confidence with our PRINCE2® Practitioner Course – Join now!

Challenges of Lean Project Management

While Lean Project Management provides several key benefits, it is essential to be aware of certain challenges that come with it. Let’s look at them below:

1) Inventory Problems

It treats excess inventory as waste and encourages stock levels as low as possible. This increases reliance on suppliers to deliver materials faster and with accuracy. Any disruption in the supply chain can delay work and affect project timelines.

2) Implementation Costs

Implementing Lean Project Management requires replacing existing systems and redesigning processes. Organisations may require investing in new tools, equipment, and training. These costs can be challenging for small-sized teams or financially unprepared ones.

3) Difficult Change Over

Shifting to Lean Project Management needs a major change in how work is planned and executed. There can be potential resistance from employees due to uncertainty and disruption. Thus, strong leadership and clear communication are integral to managing transitions successfully.

Combine project structure with flexibility with our PRINCE2 Agile® Foundation and Practitioner Course – Sign up soon!

Practical Lean Project Management Tips

Making Lean Project Management work in real-world settings requires practical, everyday habits. Here are some of the tips that you can follow for your teams:

1) Simplify Workflows

Making things too complicated can waste time, cause confusion, and lead to mistakes. Lean works best when everything is clear and simple. By keeping workflows easy to follow and removing extra steps or tools, your team can stay focused and deliver work that truly matters.

Tips to Simplify:

1) Use visual tools like Kanban boards or checklists

2) Minimise the need for approvals or handovers

3) Standardise common tasks and templates

2) Encourage Team Collaboration

Even if you're managing the project, your team members often know the most about how tasks get done. Lean encourages involving the people closest to the work in planning and improvement discussions. Their insights can help spot inefficiencies you might miss and lead to better solutions.

Why This Works:

1) Builds trust and mutual respect

2) Finds hidden blockers or bottlenecks

3) Helps align improvement efforts with real needs

3) Recognise Achievements

Lean is all about continuous improvement, and that means recognising progress. Celebrate small wins like a reduced turnaround time, smoother task flow, or fewer delays. Acknowledging these steps forward helps keep morale high and shows the team that change is working.

Ways to Celebrate:

1) Share scores that show positive results

2) Highlight individual and team contributions

3) Hold short recognition moments during team stand-ups

4) Clearly Communicate Objectives

If your team doesn’t know why you’re asking them to change how they work, they may not be fully committed to Lean practices. Clearly explaining the purpose, such as reducing waste, improving customer experience, or saving time. It helps everyone understand the big picture and feel invested in the outcome.

What to Communicate:

1) The specific goals behind the Lean initiative

2) The expected benefits for the team and customer

3) How team feedback will shape the process

Conclusion

Lean Project Management is more than just a method. It is a shift in mindset that focuses on delivering value, reducing waste, and constantly improving how your team works. Through this, you can create more efficient workflows and keep your customers at the centre of every project. Start small, stay consistent, and remember, Lean isn’t just about doing things right; it’s about focusing on the right things and cutting out what doesn’t add value.

Gain the skills to lead impactful projects with our PRINCE2 Training – Be a part of it soon!

Contact@prince2training.co.uk

Contact@prince2training.co.uk 01344203999

01344203999

Back

Back

Continue Browsing

Continue Browsing